AIRPORT UPDATES

REVIEW THE RESTRICTIONS

Maintenance

The QS3 Hushkit System was designed to meet extraordinary standards of reliability, low maintenance and quality. There are no time- or cycle-limited components in the QS3 system. All maintenance requirements are "on-condition" only,meaning that maintenance is never mandatory, but always based on the state of the QS3 hushkit. This is possible as a result of sophisticated engineering, durable material choices and manufacturing processing excellence.

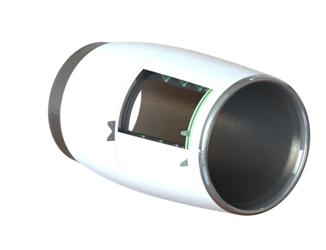

The ejector is comprised of a conventional aluminum cowling enclosing a welded titanium honeycomb core that will withstand the temperatures, pressures and resonances of the jet exhaust. The thrust reverser is a highly efficient and proven cascade design manufactured primarily from titanium. The simple, robust design requires only visual inspections during routine scheduled aircraft maintenance, meaning that your aircraft is never grounded for longer than it would be without the installation of the QS3 Hushkit System.

Structural reinforcement of the rear fuselage and the use of the cascade-style thrust reversers eliminate induced stresses on the empennage that were manifest with the OEM thrust reverser. This new system reduces the need to inspect for failed clips in the tail structure.

View THIS chart to see a comparison between the matching schedules for OEM and QS3 maintenance inspections.

Maintaining the QS3 System

The QS3 Noise Suppression System is designed for performance, durability and low maintenance. Modern technologies, materials and components that comprise the system ensure a lifetime of trouble-free service. Nineteen OEM “Inspection or Check” maintenance requirements are eliminated with installation of the QS3 System.

The periodic inspections required by Gulfstream in the aircraft Maintenance Manual are sufficient to ensure continued airworthiness. To address the structural and mechanical changes to a QS3 aircraft, owners are provided a comprehensive Maintenance Manual Supplement which details the features and components of the system and provides instructions for inspection, repair or replacement of parts if “on-condition” maintenance is required.

Fuselage and Pylons

The aft fuselage modifications and ejector-suppressor pylons are structurally consistent with the original design parameters of the Gulfstream airframe. The required periodic inspec¬tions detailed in Chapters 53 and 54 of the aircraft Maintenance Manual are sufficient. There are no are no additional inspections of the airframe or maintenance require¬ments associated with the QS3 system.

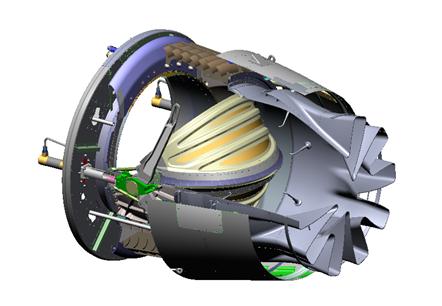

Thrust Reverser

Unlike the OEM’s thrust reversers, the QS3’s thrust reversers have no “Manufacturer’s Mean Time between Overhaul or Scrap” items. The 4,000-landing overhaul requirement is eliminated and there are no “Life-Limited Components” or “Special Inspections” consequential to installation of the QS3 system. The thrust reversers are constructed primarily of titanium for high strength, light weight, durability and corrosion resistance. All moving parts have permanently lubricated bearings to provide lifetime elimination of servicing requirements.

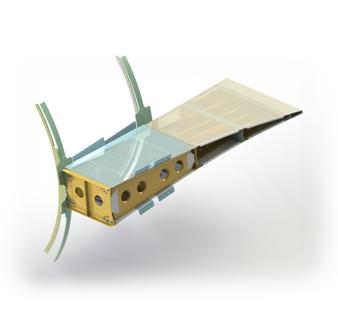

Ejector Suppressor

The ejector-suppressors, constructed of corrosion-resistant aluminum alloy with titanium used on the hot sections are permanently mounted to the airframe. The titanium honeycomb core is continuous-fusion welded to inner and outer perforated titanium sheet cylinders. There are no moving parts and the ejectors have no maintenance requirements for the life of the system, other than visual inspections concurrent with other OEM periodic requirements.