AIRPORT UPDATES

REVIEW THE RESTRICTIONS

Innovation

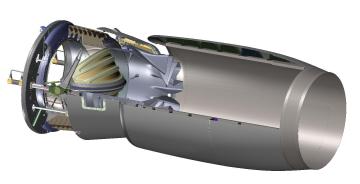

Three Components, One Efficient System

The QS3 Hushkit system consists of three major components – an alternating-lobe exhaust

nozzle, a fuselage-mounted acoustically-lined ejector, and a cascade-style thrust reverser

– that work together to deliver maximum noise absorption while maintaining superior

engine performance.

Patented Alternating-Lobe Nozzle Provides High Mixing Efficiency

QS3's nozzle has ten lobes, five shallow and five deep, alternating around its circumference to

allow deep penetration of the high-velocity jet exhaust, effectively mixing the hot exhaust

with ambient air to lower the temperature and velocity – without thrust loss.

The alternating lobes set up separate axial vortex patterns that interact with each other to enhance mixing. By breaking up the jet core into ten smaller cores, the nozzle shifts the low-frequency jet noise to a higher frequency that can be more easily absorbed. What makes this patented nozzle unique is its ability to reduce the noise without degrading the engine's performance.

The effect of QS3's rapid mixing is illustrated below in the Stage 3 exhaust velocity cross-section, and compared to cross-sections of Stage 1and 2 exhaust systems. Both the velocities and the length of the maps are non-dimensional for comparison. The high-velocity center of the jet exhaust (the jet core) is represented in red. The lowest velocities are represented in blue.

Fixed Titanium-Core Ejector Offers Durability and

Unsurpassed Noise Suppression

QS3's ejector is 36" in diameter and 73.7" long. These dimensions were determined by extensive

FAA-witnessed ground and flight testing which established a minimum size for attenuating the

Spey 511-8 exhaust noise to Stage-3 standards. The ejector is securely attached to a

reinforced fuselage via short pylons that fair into the existing engine pylons, providing

streamlined airflow with improved structural integrity.

The injector inlet is designed to deliver continuously-accelerating airflow for optimum exhaust mixing with minimum loss of energy. The perforated ejector core is a fusion-welded, titanium-honeycomb

structure with an acoustic lining on its outer surface – that will not delaminate.

The superior design and lightweight construction of this fixed titanium-core ejector offers maximum sound absorption, low drag, and unmatched durability to withstand the high temperatures and vibrations of jet engine exhaust.

Cascade-Style Thrust Reverser Generates Highest Stopping Power

The QS3 Hushkit system includes new, state-of-the-art cascade-style thrust reversers which

dramatically reduce the amount of engine power needed to provide the same reverse thrust. As a

result, the operator also benefits from reductions in:

- reverse-thrust noise, both in-cabin and external;

- temperatures, stresses and vibration loads on the engine; and

- empennage vibrations and associated fatigue-inducing stresses.

Each combined thrust reverser and mixer nozzle assembly weighs 125 pounds less than the OEM unit it replaces, thereby reducing the cantilevered loads on the engine rear flange. The thrust reverser is a form, fit and functional replacement designed for high reliability and low maintenance.